By Gary Roden, TDIndustries

On every complex construction project, individuals representing dozens of companies are brought together to design and construct a unique structure that will meet the unique budget and functional needs of the end user. The technical expertise and persistent efforts of hundreds — even thousands — of highly trained individuals are required for a successful project. While participation in the design and construction industry is both satisfying and rewarding, that does not mean it’s an easy process.

The good news: advancements in building design and construction technology are making daily life easier for the millions of people who work in this industry.

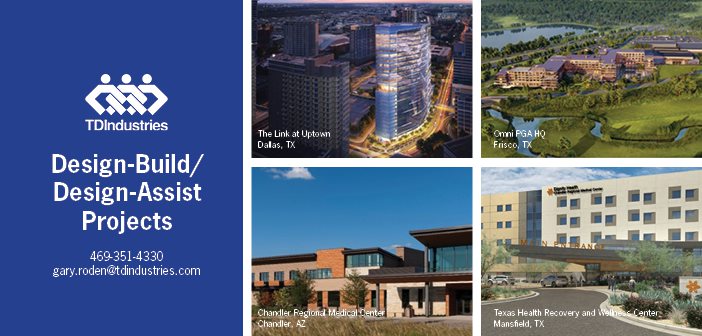

Design-Build Solutions for Complex Projects

Using design-build processes that incorporate decades of subcontractor expertise on construction jobsites into the early stages of the project allows talented design professionals to create more accurate construction documents.

These documents allow for a more efficient and cost-effective process of actually building the facility. This construction method offers a consistent model and singular responsibility from estimate and design through manufacturing and construction. Technology allows for an efficient transfer of data back and forth from the design model to the estimating model. Throughout the design process, the estimate can be checked to assure conformance to the original budget.

Once the design is complete, the model can then be utilized to prefabricate assemblies that will be transported to the job site and installed. Creating these assemblies in a manufacturing environment saves labor, improves product quality and enhances safety on the jobsite.

TDIndustries’ expertise in engineering, mechanical construction, and full facility life-cycle services — including building controls, service, and facilities management — brings innovation through experience and integrated design.

Mechanical, Electrical, Plumbing (MEP) Design-Build Benefits

Faster To-Market Schedule

In a world in which timely sourcing and obtaining quality products can no longer be taken for granted, the design-build process allows the construction team to identify and approve materials and equipment earlier in the process. Approving and ordering these building components earlier in the process helps assure that they do not become critical path delays later in the project.

Trusted Partner Responsible for Entire Project

Your single point of contact leads design management, project coordination, scheduling and problem-solving with a clear understanding of your vision and goals. Simply involving the construction team in early decision-making discussions helps to assure that they are aligned with the owner’s and design team’s goals when issues are resolved later in the project.

Innovative Solutions

Design innovation optimizes efficiency and improves constructability. Making decisions about pre-fabrication and modular construction after a design is complete is inefficient and extremely restrictive. Innovative approaches to how the project will be constructed should be an integral part of the design process.

Definitive Pricing

Why wait until a full set of construction documents is produced to know if the project will be within budget? Instead, identify the budget early, engage subcontractors in the design process, provide owners with real-time cost information with which to resolve critical design and scope issues and allow the entire team to have a voice in how the design will incorporate all the owner’s requirements while simultaneously maintaining the budget.

Labor Availability

As the industry continues to recover in a post-pandemic world, shortages of skilled labor will be the single most challenging aspect of successfully completing large, complex construction projects.

The question for owners and general contractors is, “How can I assure that the quantity of qualified craft workers will be available for my project?” One answer is to secure a commitment for that manpower earlier in the process. By engaging qualified subcontractors early in the design process, projects receive assurance from those subcontractors that their labor is committed to the project. This applies to both project leadership and skilled trades professionals.

Why Design-Build with TDIndustries?

Experience

In the past five years, TDIndustries has completed more than $2.5 billion in design-build/design-assist work.

Proven Value

Engineering – Capacity, flexibility, culture

DfMA – Integrated design with prefabrication and modularization

Design to specific equipment requirements for maximum efficiency

Constructability method/means – Incorporated into design

Early commitments – manpower, equipment, materials

Quality and budget assurance

Get Started Today

Do you want to learn more about this revolution that is occurring in the design and construction industry? Do you want to better understand how you can reduce risk related to budget, schedule and quality assurance on your next project? Contact us via email at [email protected].

About the Author

Gary Roden is TDIndustries’ Vice President, Design-Build and Business Development for North Texas. He has extensive design-build and design-assist mechanical design and construction experience gained from his 36 years in the industry. His diverse background includes architecture, MEP engineering and design, controls, automation, general contracting, and program management.