PRECONSTRUCTION MANAGER

MARKETING MANAGER

INTERVIEWEES: Cameron Smith (Preconstruction Manager) and Shelby Powell (Marketing Manager)

PROJECT NAME: Industrial Distribution Corporation Facility Move

PROJECT START DATE: September 1, 2018

PROJECT COMPLETION: February 2019

ARCHITECT: Cross Architects

OWNER: Industrial Distribution Corporation

PROJECT DELIVERY METHOD: Design Build

MAJOR TRADE PARTNERS: Action Fire Pros; Advanced Paving Acquisition, LTD; Alpha Testing; Artex Overhead Door Co; Cambridge Fence Services; Commercial Fireproofing & Insulation, LP; Core Safety; Cross Architects, PLLC; Dallas Mechanical Group; DFW Movers & Erectors, Inc.; Endur Contractors, LLC; FireCad; Hercules Relocation LLC; Malin USA; McSweeney Commercial Painting, Inc.; Quality Floors Contract Inc.; R & B Roofing; RJT Door & Service, Inc.; RLG; Rocksteady Construction, LLC; Rosas Brothers Construction, LLC.; SWC Concrete Specialist, LLC; Teks North America Solutions, Inc.; Texas Specialties & Installation Inc.; Walker Engineering; Walker Industrial LLC; WCCW, Inc.; Dallas Window & Glass

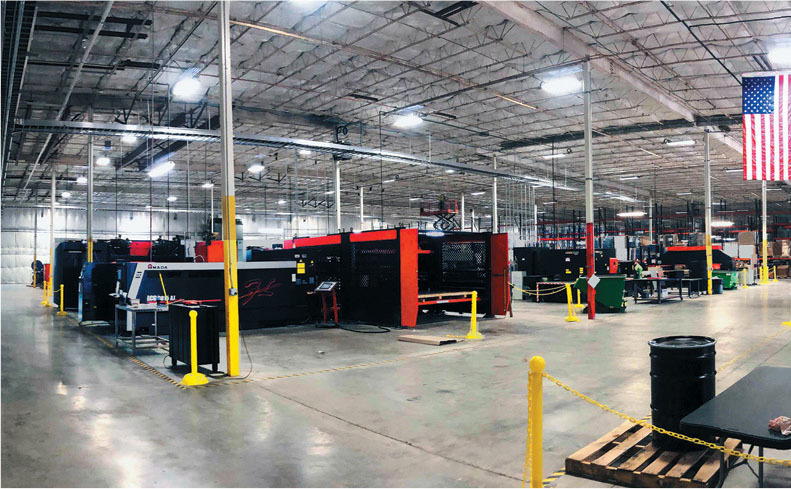

PROJECT DESCRIPTION: C1S took Industrial Distribution Corporation (IDC) from a 103,000 square foot cold dark shell to entirely moved in with commissioned, up and running equipment ready for production and finished office space in 22 weeks. The tight schedule was the driving factor for all design and construction and with over 100 pieces of manufacturing equipment coordination meetings were imperative. C1S met with the Original Equipment Manufacturers, movers and owners to develop a detailed, phased construction schedule. A numbering system was used to keep track of every piece of moving equipment, where it was coming from, the destination, and its timing on the schedule all correlated to the individual number. This ensured that the correct pieces were being moved at the appropriate times and to the proper location so the utility design would match the equipment hook-ups. The facility move was motivated by the need to raise production and the way in which C1S phased the building improvements and equipment move, IDC never had to cease complete production of their operations, keeping another family-owned business like IDC with a flow of revenue and not putting them behind in their own production schedule was the most substantial accomplishment for this project.

Q: THIS EDITION OF IN FOCUS IS FOCUSED ON TECHNOLOGY. WHAT PROACTIVE MEASURES DID THE TEAM EMPLOY TO MAINTAIN A LEVEL OF TECHNOLOGICAL INNOVATION DURING THE LIFE OF THE PROJECT?

A (Cameron): We used Procore’s project management software from the very start of the design phase and utilized it all the way through construction. As the project manager, I could make sure all design iterations and checklists went into Procore from the initial design phase, and then the superintendents all had field iPads loaded with Procore, so they could access everything on-demand onsite. It was a great tool to keep them on track.

Q: WERE THERE ANY SPECIFIC TECHNOLOGICAL ADVANCEMENTS REQUESTED BY THE OWNER?

A: IDC maintains operations of 3 distinct companies under one roof, so there were numerous networking, security and infrastructure requirements to meet. That in addition to their inventory of industrial equipment, required the electrical and networking infrastructure to support their growth. They also specifically requested two, 75-ton air rotation units, which are more energy and cost efficient for a large space like this. They also have less, easier, and safer maintenance than your traditional, roof-mounted HVAC systems.

Q: HOW MANY PEOPLE WERE ONSITE AT THE PEAK OF THE PROJECT?

A: Around 50 workers at peak. Additionally, we also had a phased employee move-in during construction, which grew from 15 employees getting equipment set up to full occupation (100+ employees) by the end of construction.

Q: WHAT OTHER ASPECTS SET APART THIS PROJECT?

A: The accelerated timeline and limited production downtime drove how we scheduled the entire project, including the moving and commissioning of over 100 pieces of equipment from their assembly lines as well as sheet metal manufacturing, which we were heavily involved in. We had to coordinate extensively with the ownership and leadership team to plan a phased approach utilizing a numbering system that assigned a number to each piece of equipment and showed exactly when, where, and how that item was going to be moved. The timing was based on the client’s company growth to ensure minimal downtime. They couldn’t afford to fully shut down operations after having a record year in 2018.

There was also the design-build aspect – we had the entire project from cradle to grave. Plus, the vast majority of the work occurred during a low production time of the year due to the Thanksgiving, Christmas, and New Year’s holidays.

Q: WHAT CHALLENGES DID YOU FACE ON THIS PROJECT?

A: All of the planning and coordination during the design phase was a challenge in and of itself.

Any time you’re getting into an existing building, you inherit some existing problems in terms of electrical, plumbing, building envelope, etc. from multiple previous tenants. The building had an older roof, which had a significant impact. We didn’t have to do a complete re-roof, but it was pretty leaky when we first came in.

Being in Irving where the soil has a lot of clay, we had to contend with a lot of sinking and swelling in the ground. We had modifications to ramps and an employee door to meet ADA requirements, and a great deal of shift in the surrounding soil is not exactly conducive to ADA compliance.

We also had to make sure people were safe while moving the many pieces of large, heavy equipment. From our and our trade partners’ workers to the IDC employees themselves safety was always the first priority. DFW Movers were the ultimate professionals and were huge resource to us in making sure everyone went home safe and sound.

Q: WHAT WAS MOST EXCITING ABOUT BUILDING THIS PROJECT?

A: For me, it was the clients. I really enjoyed working directly with a father-son team and seeing their growth and trajectory get them to a point where they could move from disjointed strip mall spaces into a single industrial warehouse space. Helping a small, family-owned business realize their dreams and take the owner’s big vision and make it a reality was huge, especially since C1S Group is a familyowned business ourselves.

It was also exciting to be able to utilize our strengths and experiences in the industrial and manufacturing space. We applied lessons from Frito-Lay and other large-scale industrial projects and were able to scale and tailor them to this small, locally owned business. It really was a perfect project for C1S’s skill set.

Q: HOW DID YOU MAINTAIN A SPIRIT OF COLLABORATION THROUGHOUT THE LIFE OF THE PROJECT?

A: We bought lunches for the subcontractors, owners, etc. and enjoyed breaking bread together. The owner even brought lunch onsite for us on first day we were here. Overall, there was a significant level of input and collaboration from ownership, as they’re a small company and very invested in their facility. We also facilitated weekly site meetings and safety awards for the workers.

Q: WHAT DID YOU DO TO KEEP THINGS FUN ON THE JOBSITE?

A (Shelby): That’s a big part of the C1S culture – work hard, play hard. It’s important for us to live a work-life balance and spend time with the team doing things together. We also allowed teams to work flexible hours (e.g., a 5:30 a.m. – 2:00 p.m. schedule) during the holiday season, so that people could spend plenty of time with their families.

Q: WHAT IS SOMETHING THAT SETS C1S GROUP APART FROM YOUR COMPETITION?

A (Cameron): First and foremost, safety is our number one priority. We have people say that our jobsites are night-and-day to some other jobsites in terms of our diligence in maintaining a safe work environment. We’ve gone 15 years with zero losttime safety incidents.

We have also a level of care (or what I like to call “give a sh∗t”) to get close with our clients. We don’t go after projects; we go after clients. We strive to get to know the client and grow a relationship into a partnership and a true value-add.

Additionally, we have substantial experience with shutdown work, and with coordinating tight schedules and strict budgets, that was all important for the client. We generally focus on existing buildings, so we have expertise in renovations like this one. Plus, our in-house design capabilities and technical resources set us apart. We have licensed engineers onsite to work with the team and consult on construction projects.